SLS as a Core Cleaning Ingredient

Sodium Lauryl Sulfate (SLS) is one of the world’s most widely used anionic surfactants, playing a fundamental role in detergents, personal care products, industrial cleaners, and countless other formulations. Its excellent ability to generate foam, reduce surface tension, and enhance cleaning power has made it indispensable to manufacturers globally.

In Singapore, SLS demand continues to grow as the country functions as a central hub for detergent manufacturing, chemical formulation, and specialty cleaning product innovation. The region’s preference for high-performance surfactants ensures that SLS remains a key ingredient for both local production and re-export to markets across Southeast Asia, South Asia, and Oceania.

From 2025 to 2035, the SLS market is expected to shift rapidly toward palm-based feedstock and eco-friendly production systems, driven by sustainability targets, regulatory pressures, and technological advancements. Singapore’s unique position at the intersection of logistics, R&D, and clean-chemistry innovation makes it a defining player in shaping the future of SLS.

Chemical Overview and Functional Strength

SLS is derived from fatty alcohols, traditionally produced from either palm kernel oil (natural origin) or petroleum-based sources. As an anionic surfactant, its structure includes a hydrophobic tail and a hydrophilic sulfate head group, giving it excellent ability to remove oils, dirt, and organic residues.

Its exceptional foaming property distinguishes it from many alternative surfactants. In personal care products such as shampoos and toothpastes, dense foam is directly associated with product quality. In detergents, foam helps lift mechanical soil and improves washing performance. This has made SLS one of the most preferred surfactants in both low-cost and premium cleaning formulations.

The compound is also highly compatible with a wide range of co-surfactants, including SLES (Sodium Lauryl Ether Sulfate), cocamidopropyl betaine, and palm-derived amides like PKDEA. These synergies further enhance foam stability, viscosity, and mildness, allowing formulators to create differentiated product profiles that match diverse consumer expectations across Asia.

Global Market Outlook and Singapore’s Strategic Position

The global Sodium Lauryl Sulfate market is projected to reach USD 1.9 billion by 2035, growing at an estimated CAGR of 4.2% from 2025 onward. Growth is driven by rising hygiene awareness, expansion of personal care industries, and increased demand for effective household detergents.

Singapore serves as a critical node within this global market. As a major re-exporter of surfactants and chemical additives, the country imports raw materials from Malaysia, Indonesia, India, and the Middle East, and supplies finished surfactants and formulated chemicals to regional manufacturers. Its world-class port infrastructure allows rapid movement of SLS to markets in Southeast Asia, Australia, and East Asia.

Additionally, Singapore’s advanced chemical R&D ecosystem including laboratories, pilot plants, and formulation centers supports innovation in SLS-based cleaning products. This strengthens the nation’s role not just as a trading hub, but also as a catalyst for sustainable detergent chemistry.

Palm-Based Feedstock: A Sustainable Advantage

-

The Rise of Palm Kernel Oil as a Feedstock

Palm-based fatty alcohols offer one of the most important routes for SLS production, especially in Asia. Palm kernel oil (PKO) provides a renewable and abundant source of lauric acid, which is essential for generating high-quality SLS with strong foaming properties.

-

Environmental Benefits Over Petrochemical SLS

Compared to petroleum-based routes, palm-derived SLS has a lower carbon footprint and aligns more closely with global demands for sustainable surfactants. Singapore-based suppliers increasingly rely on certified palm derivatives to meet consumer and regulatory expectations.

-

RSPO Certification and Traceability

SLS producers are adopting RSPO-certified palm kernel oil to ensure responsible sourcing. This meets the requirements of global FMCG brands and supports Singapore’s sustainability commitments under the Green Plan 2030.

SLS Applications in Household, Industrial, and Personal Care Markets

-

Household Cleaning Products

SLS is a key ingredient in laundry detergents, dishwashing liquids, all-purpose cleaners, and powder detergents. Its strong cleaning action and affordability make it a staple in Southeast Asian households, where value-oriented products dominate the market.

-

Personal Care and Cosmetic Applications

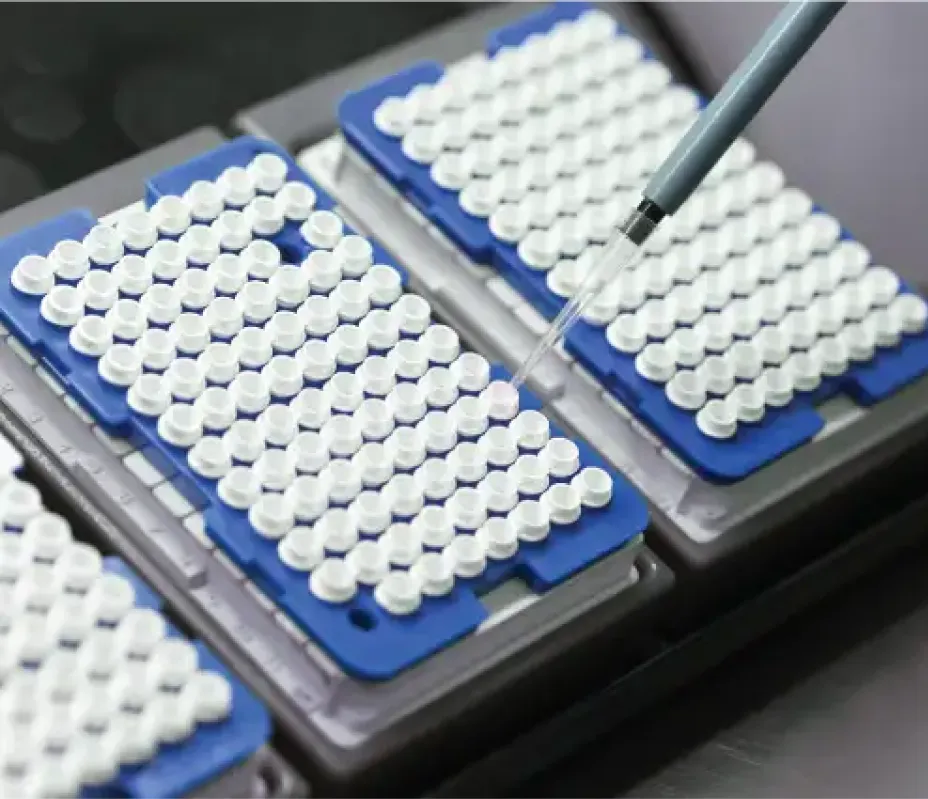

SLS enhances lather in shampoos, body washes, facial cleansers, and toothpaste. In Singapore’s premium personal care segment, SLS is often combined with milder co-surfactants to balance performance and skin compatibility.

-

Industrial and Institutional Cleaning

In industrial cleaners, SLS provides excellent degreasing performance, making it a preferred choice in automotive, manufacturing, and food-processing facilities across Asia. Its stability in both soft and hard water expands its utility across diverse environments.

Eco-Friendly Innovations and Green Manufacturing Trends

-

Low-Ethylene Oxide and Cleaner Synthesis

Manufacturers are adopting low-emission and low-EtO (ethylene oxide) production processes to reduce environmental impact and improve product safety. Singapore’s chemical plants increasingly use optimized reactors to minimize waste generation.

-

Biodegradable SLS Grades

As biodegradable cleaning agents gain traction, palm-based SLS is increasingly positioned as a renewable alternative to harsher synthetic surfactants. Its natural degradation pathway supports eco-label certifications.

-

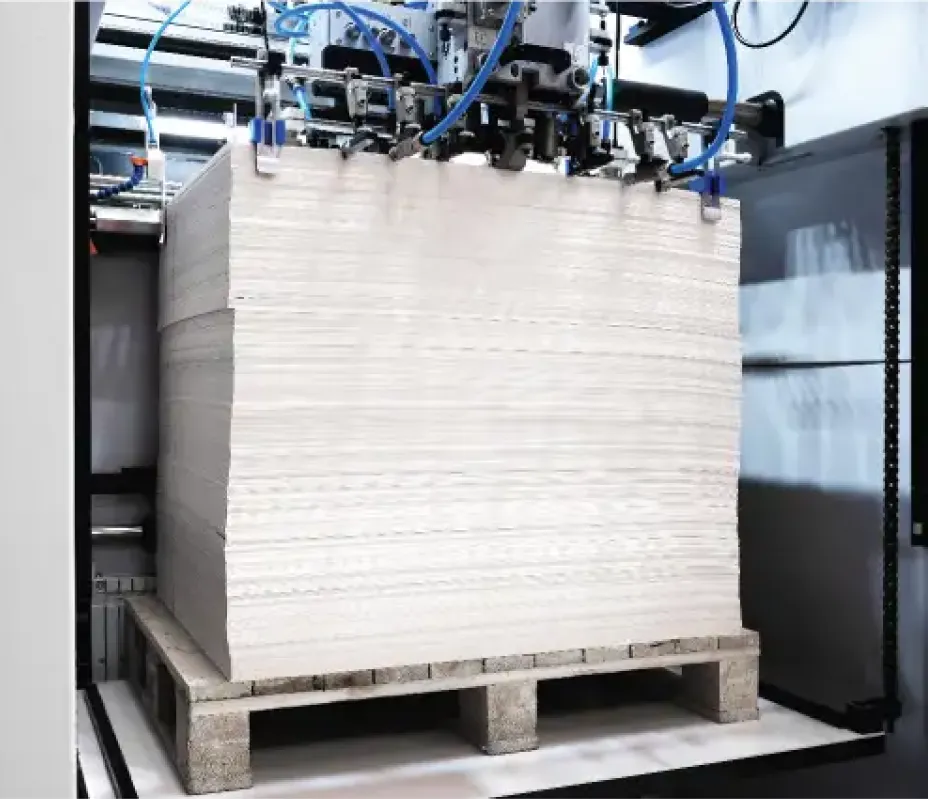

Energy-Efficient Production Technologies

Advances in drying, sulfonation, and continuous processing systems reduce energy use and enhance purity. These innovations align with Singapore’s push for greener chemical manufacturing through sustainable technology adoption.

Regulatory Standards and Compliance Across Asia

-

ASEAN Cosmetic Directive (ACD) Compliance

SLS used in personal care products in Singapore and neighbouring countries must meet stringent purity and safety standards under the ACD. This reinforces demand for high-quality and well-regulated SLS grades.

-

Environmental Regulations on Surfactant Disposal

Countries across Asia, including Singapore, Malaysia, and Thailand, have tightened wastewater discharge rules. SLS producers must meet higher levels of biodegradability and cleaner synthesis requirements.

-

Labeling, Safety, and Traceability

Regulators increasingly require transparent ingredient labels and traceability documentation. As a result, Singapore-based SLS suppliers prioritize supply chain integrity and quality certification.

Singapore’s Leadership in Surfactant R&D and Logistics

-

Advanced Research Ecosystem

Singapore’s strong R&D ecosystem including A*STAR, NTU, and chemical research institutes contribute to new surfactant technologies, improved purification techniques, and eco-friendly formulations of SLS and related compounds.

-

Hub for Regional Distribution

As Asia’s leading logistics hub, Singapore ensures fast and reliable transport of SLS to manufacturers across ASEAN, India, China, and Australia. Strategic warehousing and blending facilities enhance supply chain efficiency.

-

Anchor for Green Surfactant Innovation

Singapore’s sustainability targets encourage manufacturers to invest in greener surfactant technologies, including bio-based variants, high-purity palm-derived SLS, and blends with environmentally preferred co-surfactants.

Market Outlook 2025–2035: Opportunities and Challenges

Conclusion

Sodium Lauryl Sulfate remains one of the most important surfactants supporting modern cleaning, personal care, and industrial applications. Its superior performance, cost-effectiveness, and compatibility with palm-derived feedstock ensure strong long-term demand across Asia, particularly in value-driven detergent markets.

As the world transitions toward cleaner chemistry and eco-friendly production systems, palm-based SLS offers manufacturers a renewable, effective, and increasingly sustainable solution. Singapore’s leadership in chemical logistics, R&D, and sustainability innovation places it at the heart of these advancements.

Looking ahead to 2035, SLS will continue evolving through improved production technologies, greener raw materials, and enhanced safety profiles ensuring its place as a future-ready surfactant for both mainstream and emerging cleaning applications. For sourcing guidance, technical support, or high-quality SLS solutions tailored to your cleaning and personal care formulations, you can reach our team through the Contact Us page at Chemtradeasia Singapore.

References

English

English

Indonesian

Indonesian

简体字

简体字

العربية

العربية

Español

Español

Français

Français

Português

Português

日本語

日本語

한국어

한국어

Tiếng Việt

Tiếng Việt

Leave a Comment