Introduction

In the heart of Singapore's advanced and space-constrained food and chemical industries, ingredient stability is not just a preference it is an absolute necessity. Among the pantheon of essential ingredients, milk powder stands out as a cornerstone of modern manufacturing. This versatile dairy derivative, achieved through processes like spray drying, transforms perishable liquid milk into a stable, transportable, and immensely functional powder. For a nation that imports the vast majority of its food and raw materials, the extended shelf life and reduced logistical burden of milk powder are critical advantages that directly support food security and manufacturing resilience.

This article delves into the multifaceted role of milk powder as a key industrial ingredient. We will explore the scientific principles behind its remarkable stability, the factors that dictate its shelf life, and its diverse applications across Singapore's dynamic food, beverage, and even chemical sectors. Furthermore, we will provide crucial insights for businesses on sourcing high-quality milk powder from reliable suppliers like Chemtradeasia, ensuring that the backbone of their products is both robust and dependable.

The Science of Stability: Why Milk Powder is a Manufacturing Marvel

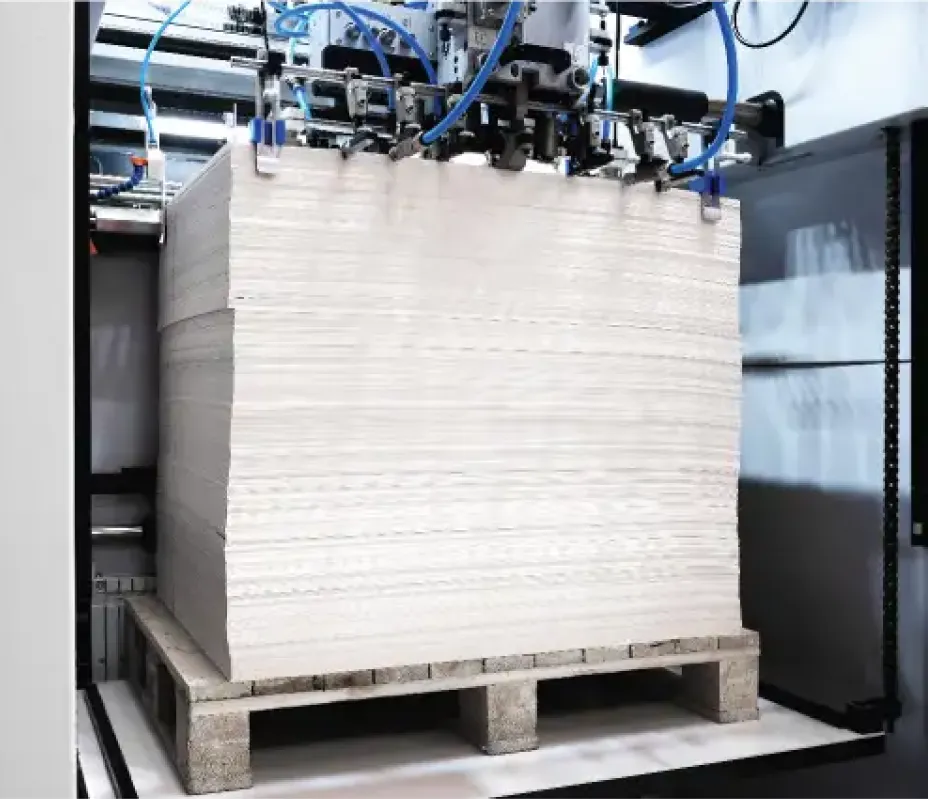

The transformation of milk into powder is a feat of food engineering designed primarily to enhance stability. The core process, spray drying, involves atomizing concentrated milk into a hot air chamber, where instantaneous evaporation removes the majority of water. This drastic reduction in water activity (aw) is the primary guardian against microbial growth. Most bacteria, yeasts, and molds require a high aw to proliferate; by lowering it to typically below 0.2, spray dried milk powder becomes microbiologically stable and safe for long-term storage at ambient temperatures, a vital trait in Singapore's tropical climate.

Beyond microbiology, the stability of milk powder encompasses chemical and physical properties. The powder's low moisture content also slows down deleterious chemical reactions like Maillard browning and lipid oxidation. However, these reactions are not eliminated. The structure of the powder particles, influenced by drying parameters, affects solubility and flowability key functional attributes for industrial use. High-quality skim milk powder, with its fat removed, offers even greater oxidative stability compared to whole milk powder, making it a preferred choice for applications where neutral flavor and extended shelf life are paramount. This inherent stability translates directly to manufacturing efficiency, reducing waste, simplifying inventory management, and ensuring consistent product quality batch after batch.

Maximizing Shelf Life: Factors and Best Practices

While inherently stable, the shelf life of milk powder is not infinite and is influenced by a confluence of factors. Understanding these is crucial for Singaporean manufacturers to protect their investment and final product quality. The type of powder is the first determinant: skim milk powder, due to its negligible fat content, can have a shelf life of up to 24 months when stored properly. In contrast, whole milk powder, containing milk fat, is more susceptible to lipid oxidation and rancidity, typically offering a shelf life of 12-18 months. Storage conditions are the other critical half of the equation. Heat, moisture, light, and oxygen are the principal enemies.

Best practices for storage in Singapore's humid environment are non-negotiable. Powder must be kept in a cool, dry place, ideally below 25°C and at relative humidity below 65%. Packaging plays a heroic role here; multi-layer foil bags with nitrogen flushing provide an excellent barrier against moisture and oxygen. Once opened, contents should be transferred to airtight containers and used promptly. For bulk industrial users, monitoring the powder's solubility index and free fat content over time can provide early indicators of quality degradation. Adhering to these protocols ensures that the functional benefits of the milk powder its emulsification, foaming, and browning properties are preserved until the moment of use.

Key Industrial Applications in Singapore's Market

Singapore's status as a global food innovation hub and its diverse F&B landscape create a robust demand for milk powder across numerous applications. In bakery and confectionery, it is indispensable. It provides structure and richness to bread, enhances browning in biscuits and cookies, and forms the base for chocolates and compound coatings. The dairy solids contribute to tender crusts and soft crumbs, a quality highly sought after in artisanal and industrial baking alike. In the beverage sector, milk powder is the foundation for instant milk drinks, protein shakes, infant formula, and ready-to-drink coffee mixes, categories that see consistent consumption in Singapore's fast-paced lifestyle.

Beyond these traditional uses, milk powder finds innovative roles in savory applications. It acts as a cost-effective and shelf-stable source of dairy flavor and protein in soups, sauces, gravies, and instant noodles. In processed meats, it can improve water-binding capacity and texture. Furthermore, the functional proteins in milk powder, notably casein and whey, have applications that blur the line between food and chemical industries. They are used as binders, clarifiers, and even in edible coatings. This versatility makes milk powder not merely an ingredient but a multi-functional tool for product developers across the city-state, enabling everything from luxury patisserie items to affordable, nutritious staple foods.

Sourcing Quality Milk Powder: A Guide for Singaporean Industries

For manufacturers in Singapore, procuring consistent, high-quality milk powder is a strategic decision that impacts final product integrity. The source matters immensely. Powders are classified by grade (e.g., Grade A/Extra Grade) and heat treatment (low, medium, high heat), which affects functionality. A low-heat milk powder retains more native protein functionality, making it ideal for cheese-making and yogurt production where gelling properties are vital. Conversely, a high-heat milk powder, with denatured proteins, offers better heat stability for products like soups and sauces that undergo severe thermal processing.

Partnering with a reputable and knowledgeable supplier like Chemtradeasia is crucial. A trusted supplier provides more than just product; they offer technical data sheets, certificates of analysis (COA) detailing microbiological and compositional specs, and traceability back to the origin. They can advise on the optimal powder type for a specific application, whether it's instantized milk powder for rapid dissolution in vending machines or a high-solubility index powder for reconstituted beverages. In a market like Singapore, where regulatory standards are stringent, a supplier's ability to guarantee compliance with Singapore Food Agency (SFA) regulations and provide consistent supply chain logistics is as important as the product specification itself.

The Future of Dairy Ingredients in Advanced Manufacturing

The trajectory of milk powder and dairy ingredients is pointing towards greater specialization and technological integration. The trend in Singapore and globally is moving beyond generic powders to tailored ingredients with enhanced functionalities. These include milk powder with modified protein profiles for specific nutritional or textural outcomes, agglomerated powders for instant dispersion, and powders with encapsulated fats or flavors for controlled release. The rise of plant-based alternatives is also shaping the landscape, prompting innovation in hybrid products and the development of dairy powders that offer unparalleled functional superiority in specific niches.

Furthermore, Singapore's push into food tech, including cellular agriculture and precision fermentation, may redefine dairy ingredients in the long term. However, for the foreseeable future, traditional spray-dried milk powder will remain irreplaceable for its cost-effectiveness, nutritional profile, and unparalleled functional versatility. Sustainability is becoming a key purchasing criterion, driving demand for powders from farms with certified sustainable and ethical practices. Suppliers at the forefront, like Chemtradeasia, are increasingly expected to provide products that align with these broader environmental, social, and governance (ESG) goals, ensuring that this ancient ingredient continues to meet the demands of a modern, conscientious market.

Conclusion

Milk powder is far more than a mere substitute for fresh milk; it is a technologically advanced, stable, and multifunctional ingredient that powers vast segments of Singapore's industrial landscape. Its extended shelf life and logistical efficiency solve critical challenges in an import-dependent nation, while its functional properties in baking, confectionery, beverages, and savory foods make it indispensable for product developers. The key to leveraging its full potential lies in understanding the science behind its stability, adhering to strict storage protocols, and most importantly, sourcing the right type and grade from a credible and technically adept supplier.

As Singapore continues to solidify its position as a food and innovation hub, the demand for reliable, high-quality dairy ingredients will only intensify. By making informed choices about their milk powder supply prioritizing specifications, supplier reliability, and application-specific functionality, Singaporean manufacturers can ensure product excellence, operational efficiency, and continued growth in an increasingly competitive and sophisticated market. For sourcing support, technical guidance, or high-quality milk powder tailored to your manufacturing needs, you can reach our team through the Contact Us page at Chemtradeasia Singapore.

English

English

Indonesian

Indonesian

简体字

简体字

العربية

العربية

Español

Español

Français

Français

Português

Português

日本語

日本語

한국어

한국어

Tiếng Việt

Tiếng Việt

Leave a Comment